Porcelain countertops have become a popular choice for many homeowners and designers due to their remarkable durability and elegant aesthetics. Originating from materials that have been used for centuries, porcelain offers a unique blend of beauty and resilience, making it an ideal surface for kitchens. Unlike traditional materials, porcelain is created through a sophisticated process that involves the use of fine clay rich in kaolinite, along with other natural raw materials, such as silica, feldspar, and mineral oxides. These components are carefully combined and subjected to high temperatures, resulting in a product that is both dense and non-porous.

One of the compelling reasons to opt for porcelain countertops is their resistance to stains, scratches, and heat, ensuring that your kitchen remains pristine and functional over the years. Furthermore, the versatility of porcelain allows for a wide range of designs, colors, and finishes, giving homeowners the freedom to customize their countertops to match their personal style and kitchen theme. As you delve deeper into the manufacturing process, you’ll gain insight into how these stunning surfaces are crafted, from the selection of materials to the finishing touches that make each piece unique.

Call us today at (954) 781-7370 for a free quote! Discover how Absolute Marble and Granite can transform your kitchen with our exquisite porcelain countertops.

Raw Materials and Composition

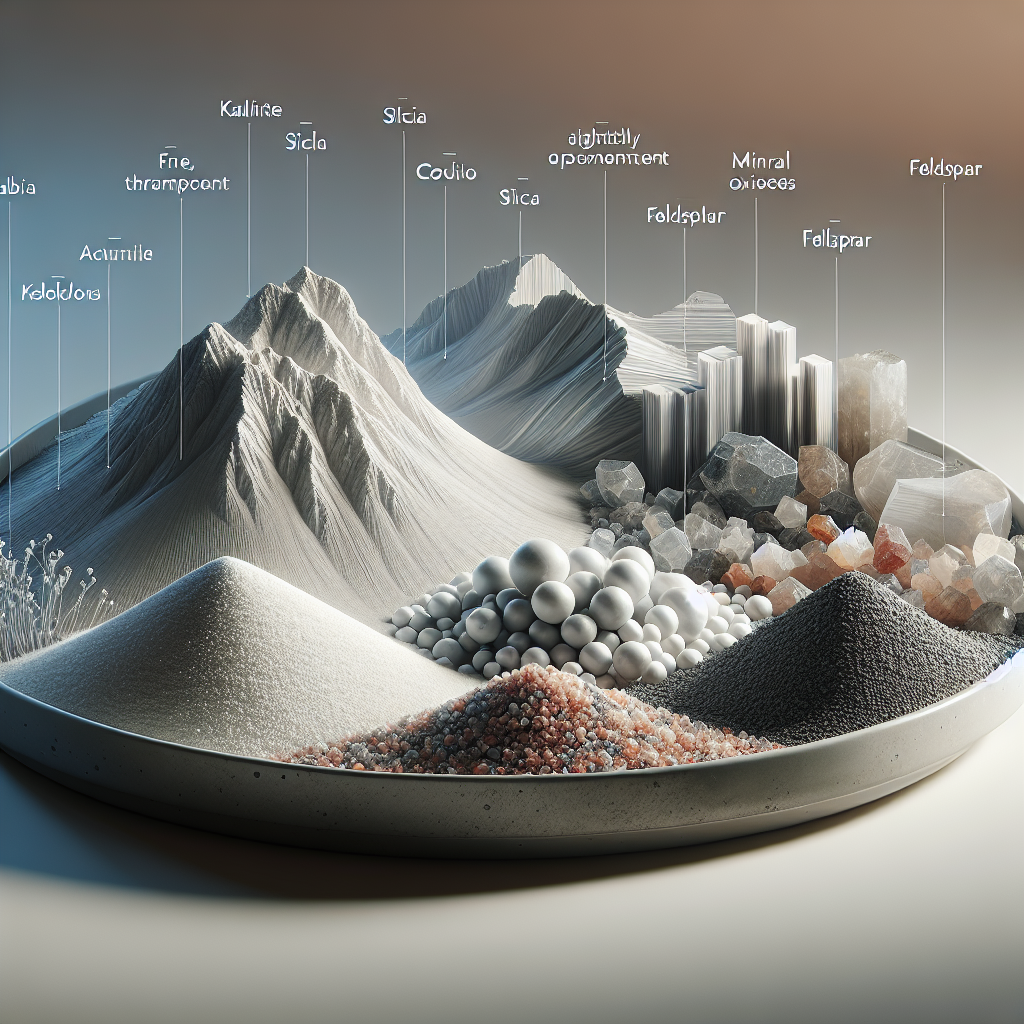

The creation of porcelain countertops begins with the careful selection of raw materials, which are essential for producing the distinctive qualities that make porcelain a top choice for kitchen surfaces. The primary ingredient in porcelain is kaolinite clay, a naturally occurring mineral that is known for its fine particle size and purity. This clay forms the base of the porcelain, providing the much-needed flexibility and strength during the manufacturing process.

In addition to kaolinite, other minerals such as silica and feldspar are incorporated to enhance the properties of the final product. Silica contributes to the hardness and durability of the porcelain, while feldspar acts as a flux, lowering the melting point and aiding in the vitrification process. This combination results in a material that is not only robust but also possesses a glass-like finish that adds to its aesthetic appeal.

To achieve the desired color and finish, mineral oxides are introduced during the mixing phase. These oxides allow for a wide spectrum of colors and patterns, enabling manufacturers to create countertops that mimic the appearance of natural stone or offer a uniform, modern look. The meticulous blending and balancing of these raw materials ensure that each porcelain slab is of the highest quality, ready to be transformed into a luxurious countertop that stands the test of time.

Manufacturing Process Overview

The manufacturing process of porcelain countertops is a meticulous journey that transforms raw materials into a refined, durable product. It all begins with the mixing stage, where carefully measured quantities of kaolinite clay, silica, and feldspar are combined with water to form a homogenous slurry. This mixture is then poured into molds to achieve the desired thickness and shape of the countertop slabs.

Once molded, the slabs undergo a process called drying, where excess moisture is removed. This step is crucial as it ensures the slabs do not crack or deform during subsequent stages. After drying, the slabs are subjected to a high-temperature firing process in a kiln. This firing stage is pivotal, involving temperatures that can exceed 2,300°F (1,260°C). Such intense heat facilitates the vitrification of the materials, resulting in the creation of a dense, non-porous, and sturdy surface.

Following the firing, the slabs are allowed to cool gradually to prevent any thermal shock. Once cooled, they are polished to achieve the desired finish. This polishing process not only enhances the visual appeal but also ensures a smooth, easy-to-clean surface. The final step involves a thorough quality inspection to check for any flaws or imperfections, ensuring that only the finest pieces make their way to the market. Through each of these stages, precision and attention to detail are paramount, culminating in porcelain countertops that are both beautiful and resilient.

Shaping and Design Customization

Once the porcelain slabs have been successfully created, the journey progresses to the exciting phase of shaping and design customization. This step is where the slabs are transformed into bespoke countertops tailored to the specific needs and aesthetic preferences of the customer. Using advanced cutting and shaping technology, these slabs can be precisely cut into various shapes and sizes, accommodating everything from standard kitchen layouts to unique, intricate designs.

The customization process begins with the cutting stage, where diamond-tipped saws and water jet technology are employed to achieve precise cuts without compromising the integrity of the porcelain. This allows for the creation of seamless edges and exact dimensions, ensuring a perfect fit within the designated space. The ability to cut with such precision opens up a world of possibilities for designers and homeowners alike, enabling the integration of features such as curved edges, integrated sinks, and tailored backsplashes.

Beyond shaping, the design aspect involves choosing the right finishes and decorative elements. Porcelain countertops can be finished in a variety of textures, from matte to high gloss, each offering a different aesthetic and functional appeal. Furthermore, digital printing technology allows for the recreation of natural stone patterns, wood grains, or any other desired designs, providing an extensive array of options to match any kitchen decor. The culmination of these processes results in a custom-crafted countertop that not only fits perfectly within its intended space but also reflects the unique style and personality of the client.

Firing and Glazing Techniques

The next pivotal stage in crafting porcelain countertops involves the firing and glazing techniques, critical processes that significantly enhance the durability and aesthetic appeal of the countertops. After shaping and customizing the porcelain slabs, they undergo a rigorous firing process in kilns, reaching temperatures exceeding 2,400°F. This high-temperature firing is essential as it transforms the raw materials into a solid, non-porous surface, ensuring the countertops are resistant to stains, scratches, and heat. The intense heat causes the particles within the porcelain to fuse together, creating a dense and robust material ideal for kitchen environments.

Following the firing, the glazing phase begins. This involves applying a thin layer of glass-like coating to the surface of the porcelain. The glaze serves multiple purposes: it seals the countertop, enhancing its stain and scratch resistance, and it also provides a glossy or matte finish that can be customized to suit different design preferences. Glazing can also incorporate various pigments and designs, allowing for a wide range of color choices and patterns, from classic whites to bold, artistic designs.

The combination of firing and glazing not only solidifies the structural integrity of the countertops but also elevates their visual appeal. The result is a stunning, resilient surface that can withstand the demands of everyday kitchen use while maintaining its beauty over time. This meticulous process ensures that each piece is not only a functional asset but also an elegant addition to any kitchen space.

Final Inspection and Quality Assurance

Once the porcelain countertops have undergone firing and glazing, they enter the crucial stage of final inspection and quality assurance. This step ensures that every countertop meets the highest standards of quality and craftsmanship. Skilled inspectors meticulously examine each slab, looking for any imperfections such as cracks, uneven surfaces, or inconsistencies in the glaze. This rigorous inspection process guarantees that only flawless products make it to the next phase.

During quality assurance, the countertops are also tested for durability and performance. This includes checking their resistance to common kitchen hazards such as heat, stains, and scratches. By simulating real-world conditions, manufacturers can ensure that the countertops will not only meet but exceed customer expectations in terms of functionality and longevity. This meticulous attention to detail underscores the commitment to precision and excellence that defines our brand.

Once the countertops pass these stringent checks, they are ready for installation, providing homeowners with a product that is both beautiful and built to last. The combination of cutting-edge technology and experienced craftsmanship ensures a final product that enhances any kitchen space.

If you’re looking for exceptional countertop solutions, look no further. Call us today at (954) 781-7370 for a free quote! Our expert team is ready to assist you in achieving the kitchen of your dreams.